Cold room panels play a critical role in the construction and maintenance of temperature-controlled environments. These insulated panels are specifically designed to provide excellent thermal insulation, ensuring that cold rooms maintain a stable internal temperature for extended periods. Cold room panels are used across various industries, from food storage to pharmaceuticals, where temperature control is essential. In this article, we’ll explore the diverse applications of cold room panels and why they are an essential component of modern cold storage systems.

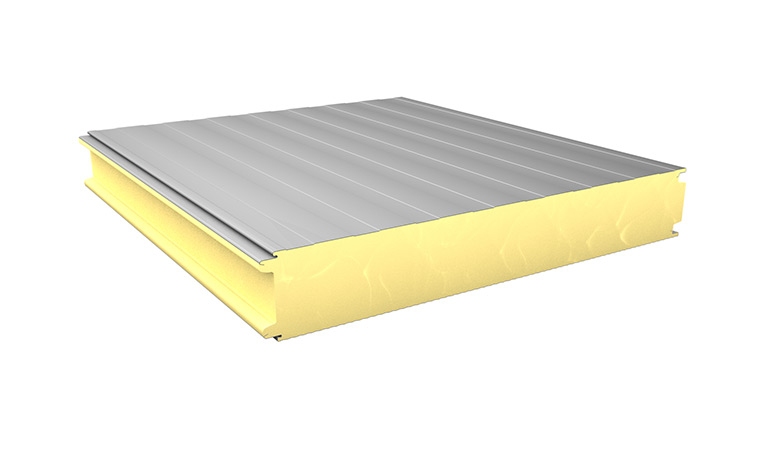

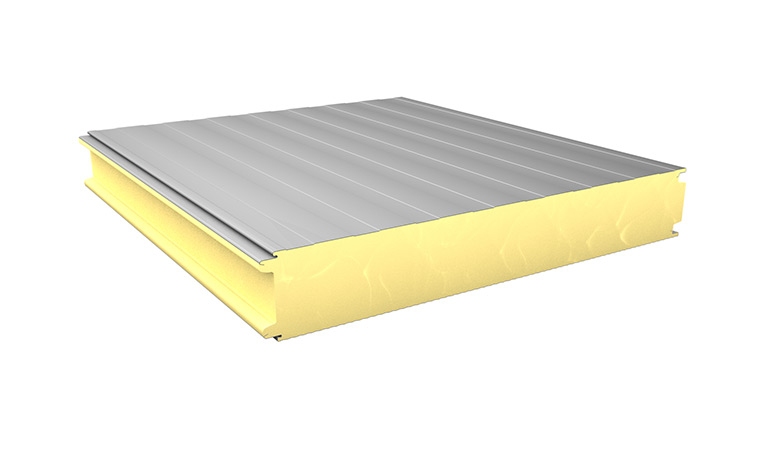

Cold Room Insulation Panel

1. Cold Storage for Food and Beverages

One of the most common applications of cold room panels is in the food and beverage industry. Cold rooms are vital for preserving perishable items such as meat, fish, fruits, vegetables, and dairy products. Cold room panels help create an airtight environment that maintains the correct temperature and humidity levels required to prevent food spoilage and maintain product freshness.

These panels also provide hygienic surfaces that are resistant to moisture, mold, and bacterial growth, making them ideal for use in food storage facilities. Their easy-to-clean nature ensures that the cold storage areas can maintain high standards of cleanliness and sanitation, essential for preventing contamination in the food supply chain.

Fruit and Vegetable Cold Rooms

2. Pharmaceutical and Medical Storage

The pharmaceutical industry relies heavily on cold rooms to store vaccines, medications, and biological samples. Cold room panels are crucial in maintaining the precise temperature ranges required for these sensitive products. Temperature fluctuations can cause some medications and vaccines to lose potency, making consistent cold storage essential for product efficacy.

Cold room panels help maintain low temperatures in storage facilities for pharmaceutical products, ensuring the safety and reliability of the supply. Additionally, medical facilities use cold rooms with insulated panels to store blood samples, organs, and other medical supplies that must be kept under controlled temperatures.

3. Cold Chain Logistics and Warehousing

Cold chain logistics involves the transportation and storage of temperature-sensitive products across various industries, from food to pharmaceuticals. Cold room panels are used to build cold storage warehouses and refrigerated trucks, where maintaining a consistent temperature is crucial for product preservation during transport.

In warehousing, cold room panels help create energy-efficient, temperature-controlled environments that meet the stringent requirements of cold chain logistics. These panels allow warehouses to maintain specific temperature ranges for various products, including frozen goods, fresh produce, and pharmaceutical supplies.

Logistics Cold Storage

4. Supermarkets and Retail Stores

Cold room panels are commonly used in supermarkets and retail stores for building walk-in refrigerators and freezers. These cold rooms store fresh and frozen food products, ensuring that they remain in optimal condition for customers. Cold room panels provide the necessary thermal insulation to maintain temperatures even with frequent door openings and closings.

Additionally, cold rooms in supermarkets often need to accommodate a variety of temperature zones within a single space. Cold room panels allow for this flexibility, enabling the creation of different temperature environments for different types of products, such as fresh produce, frozen goods, and dairy items.

5. Agricultural Cold Storage

Agricultural producers use cold rooms with insulated panels to store harvested crops before distribution. Temperature-sensitive products such as fruits, vegetables, and flowers must be kept in specific environments to prevent spoilage and extend their shelf life. Cold room panels allow farmers and agricultural businesses to store their products in optimal conditions, ensuring freshness and minimizing waste.

Cold room panels are especially beneficial for large-scale agricultural operations where maintaining consistent temperatures across multiple storage areas is necessary. The panels’ thermal efficiency helps lower energy costs, which is important for businesses looking to maintain profitability while managing large cold storage operations.

6. Industrial and Manufacturing Facilities

Cold room panels are used in industrial and manufacturing facilities that require controlled environments for processing and storing temperature-sensitive materials. In industries such as chemical manufacturing, certain raw materials and finished products must be kept at low temperatures to preserve their quality and integrity.

Cold room panels allow manufacturers to build custom cold storage spaces that meet their specific needs, providing efficient and cost-effective temperature control. These panels are highly durable, capable of withstanding the demanding conditions of industrial applications while maintaining excellent thermal performance.

FAQs About Cold Room Panels

Q: What materials are cold room panels made of?

A: Cold room panels are typically made of insulated cores, such as polyurethane foam (PUR) or polyisocyanurate (PIR), sandwiched between two outer layers of metal or plastic. The materials are chosen for their excellent thermal insulation properties and durability.

Q: How thick should cold room panels be?

A: The thickness of cold room panels depends on the temperature requirements of the storage area. Thicker panels provide better insulation and are often used for freezer rooms, while thinner panels are suitable for refrigerated spaces.

Q: Can cold room panels be customized?

A: Yes, cold room panels can be customized in terms of size, thickness, and material to meet specific project requirements. Many manufacturers offer tailored solutions for cold storage facilities, ensuring optimal performance.

In conclusion, cold room panels are essential for maintaining temperature-controlled environments across a wide range of industries. From food storage to pharmaceuticals and industrial manufacturing, these panels provide the insulation and durability needed to ensure products are preserved under optimal conditions. By choosing the right cold room panels, businesses can create efficient and reliable cold storage solutions that meet their unique needs.

Kendall offers a vast choice of cold rooms, refrigeration equipment and accessories. Whatever your application, whatever your budget, and whatever size and shape for your needs.