Water cooled condenser units are widely used in various industries to improve the efficiency and performance of HVAC systems, refrigeration units, and power plants. These systems utilize water as a cooling medium to condense refrigerants or gases, providing a reliable and energy-efficient way to manage heat exchange. In this article, we will explore the key benefits of using water cooled condenser units, and why they are an excellent choice for many applications.

1. Improved Efficiency and Performance

One of the primary advantages of water cooled condenser units is their high level of efficiency. Compared to air cooled systems, water cooled condensers are more effective at transferring heat. This is because water has a higher thermal capacity than air, allowing it to absorb and carry away more heat from the refrigerant or gas. As a result, water cooled systems are generally able to maintain a lower operating temperature, which leads to better overall performance and more consistent cooling.

With a water cooled condenser, the heat transfer process is more efficient, leading to a reduction in the amount of energy needed to keep the system running. This is particularly beneficial in industrial applications where energy consumption is a major concern, as it can significantly reduce operating costs over time.

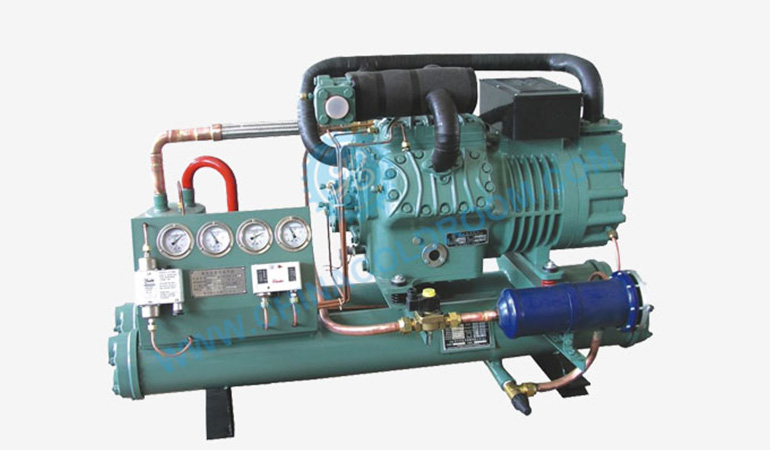

GEA BOCK Low Temperature Water Cooled Condensing Unit (-35~-25℃)

2. Energy Savings and Cost Efficiency

Water cooled condensers offer significant energy savings compared to air cooled systems. Air cooled units require larger fans and motors to expel heat from the system, leading to higher electricity consumption. In contrast, water cooled units rely on water to absorb and transport heat, which requires less energy for cooling. As water has a higher heat absorption capacity, it can handle a greater heat load with less energy input, making it a more cost-effective option in the long run.

Additionally, the water used in these systems is typically recirculated, which means the amount of water needed is relatively low, and operational costs remain manageable. The energy savings provided by water cooled condensers can help businesses lower their utility bills, offering long-term financial benefits.

3. Space Efficiency and Flexibility

Water cooled condenser units are generally more compact than air cooled systems, making them a space-efficient choice for facilities where space is limited. Since water cooled units do not require large outdoor fans and vents to expel heat, they can be installed in more confined spaces, both indoors and outdoors. This makes them an ideal solution for commercial and industrial environments where space utilization is a priority.

In addition to being space-efficient, water cooled systems also offer greater flexibility in installation. They can be integrated into existing cooling systems with minimal disruption, allowing for easy upgrades or modifications to meet changing demands. This adaptability is a key benefit for businesses that require scalable solutions that can grow with their operational needs.

4. Environmental Benefits

Water cooled condenser units can have a positive impact on the environment. Because they are more energy-efficient than air cooled systems, they produce fewer greenhouse gas emissions, reducing the overall carbon footprint of a facility. The efficient use of energy not only lowers electricity consumption but also helps reduce the demand for fossil fuels used in power generation.

Additionally, since water cooled systems use water as a cooling medium, they have a lower environmental impact compared to systems that rely on refrigerants. This is particularly important in industries that are subject to environmental regulations and sustainability goals, as water cooled condensers can help meet green building standards and reduce the environmental footprint of operations.

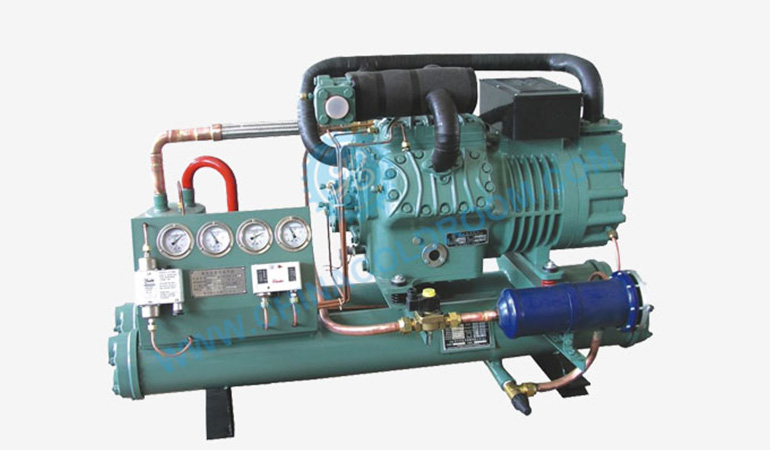

Two Stage Water Cooled Piston Condensing Unit – Large Scale Refrigeration Unit (-40~-25℃)

5. Enhanced Durability and Longevity

Water cooled condenser units are known for their durability and long service life. Since they operate more efficiently and with less strain on their components, these systems tend to experience less wear and tear compared to air cooled units. The reduced mechanical stress results in fewer breakdowns and a longer lifespan for the unit, which means less frequent maintenance and fewer costly repairs.

In addition, many water cooled condenser units are made with high-quality materials that are resistant to corrosion and degradation, ensuring that the system continues to perform optimally over time. This makes water cooled units a reliable and low-maintenance choice for businesses that need a robust cooling solution.

6. Lower Noise Levels

Water cooled condenser units typically operate at much lower noise levels compared to air cooled systems. Air cooled units use large, high-powered fans to blow air over the condenser coils, which can produce significant noise. In contrast, water cooled systems rely on water pumps and cooling towers, which operate more quietly, making them ideal for environments where noise reduction is important.

Lower noise levels make water cooled condenser units well-suited for applications in office buildings, hospitals, schools, and residential areas where noise pollution can be a concern. The quiet operation of these systems can create a more comfortable and productive environment for workers, patients, and residents.

7. Consistent and Reliable Cooling

Water cooled condensers offer consistent and reliable cooling performance, regardless of the external temperature. Unlike air cooled systems, which can be affected by fluctuations in outdoor air temperature (especially in hot weather), water cooled systems are less sensitive to environmental conditions. Since water is used to cool the refrigerant or gas, the cooling process remains efficient even during periods of high ambient temperatures.

This reliable cooling capability ensures that systems running on water cooled condensers can maintain optimal performance and avoid overheating, even in challenging climates. Whether it's a commercial HVAC system or an industrial refrigeration unit, water cooled condensers provide dependable cooling all year round.

8. Applications of Water Cooled Condenser Units

Water cooled condenser units are used in a wide range of applications across various industries. Some common uses include:

HVAC Systems: For commercial and industrial heating, ventilation, and air conditioning systems that require efficient cooling solutions.

Refrigeration Units: In food processing, cold storage, and pharmaceutical facilities where consistent refrigeration is essential.

Power Plants: For cooling the steam in thermal power plants and other industrial applications requiring large-scale heat exchange.

Data Centers: To cool servers and IT equipment, ensuring that high-performance computing systems remain at optimal temperatures.

Marine and Offshore Applications: In ships and offshore platforms where efficient and space-saving cooling systems are needed.

Conclusion

Water cooled condenser units offer numerous benefits, including improved efficiency, energy savings, environmental advantages, and long-term durability. They provide consistent, reliable cooling and can be installed in a variety of settings, from commercial buildings to industrial facilities. By reducing energy consumption and maintenance costs, these systems offer significant financial savings over time. Whether you're looking to enhance the performance of an HVAC system, refrigeration unit, or power plant, water cooled condensers are a smart choice for businesses seeking reliable and energy-efficient cooling solutions.

Searching for a Water-Cooled Condensing Units Manufacturer in China?

Kendall is Your Best Selection! Do you want to receive more information about water cooled condenser units? Then we are happy to answer your questions. Fill in the contact form or send an email to https://www.kendallcool.com.