A cold room is a critical storage facility used to preserve and store perishable goods, such as food, pharmaceuticals, and chemicals, at low temperatures to prevent spoilage and maintain their quality. Choosing the right materials for constructing a cold room is essential to ensure efficient temperature regulation, insulation, durability, and hygiene. In this guide, we will explore the best materials for building a cold room to create optimal storage conditions for your goods.

| Material | Advantages | Best For |

|---|

| Insulated Panels | Excellent thermal efficiency, low energy use | Walls & ceilings |

| Stainless Steel | Hygienic, corrosion resistant | Food & pharma storage |

Get a Free Cold Room Material Consultation

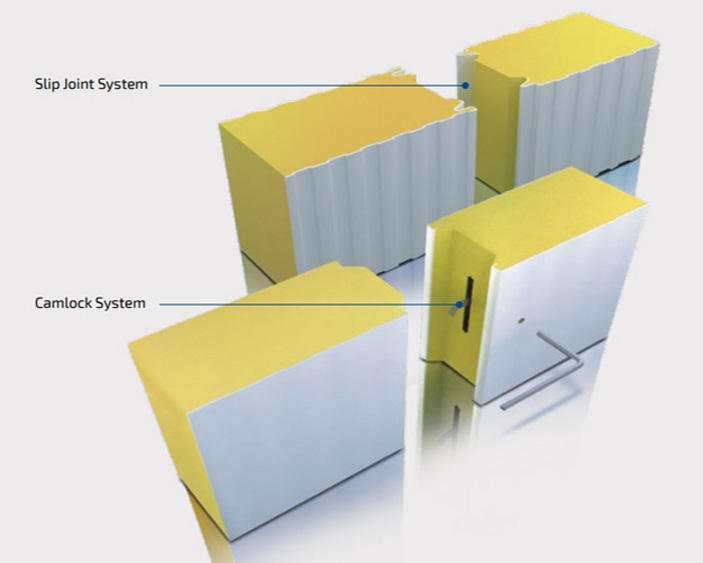

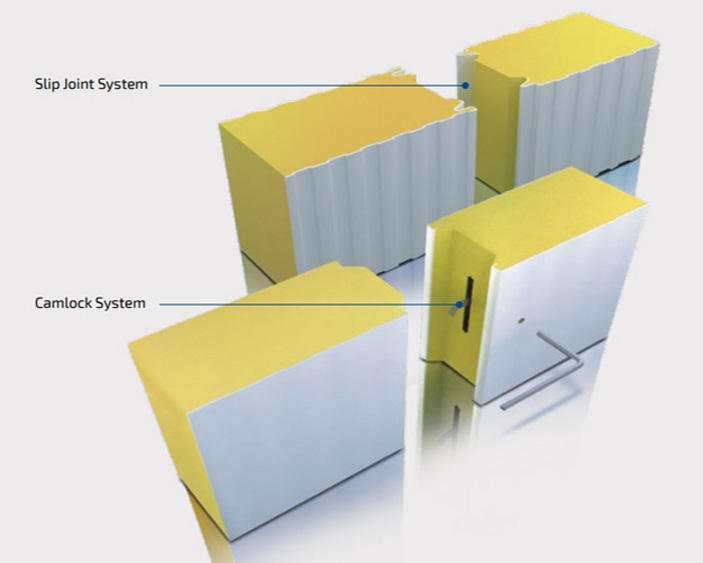

1. Insulated Panels

Insulated panels are a popular choice for cold room construction due to their excellent thermal properties. These panels are usually composed of a core material, such as polyurethane foam or polystyrene, sandwiched between two layers of metal or other sturdy materials. The insulation in these panels helps maintain a consistent and controlled temperature within the cold room, minimizing temperature fluctuations and reducing energy consumption.

2. Stainless Steel

Stainless steel is widely used for the interior surfaces of cold rooms due to its hygienic properties and resistance to corrosion. It is easy to clean and maintain, making it suitable for storing food, pharmaceuticals, and other sensitive goods that require strict hygiene standards. Stainless steel surfaces also offer excellent durability and longevity, ensuring that the cold room remains in optimal condition for extended periods.

3. High-Density Polyethylene (HDPE)

HDPE is a durable and moisture-resistant plastic material commonly used for the construction of cold room floors and ceilings. It provides a smooth and impermeable surface that is resistant to water and chemical damage, preventing moisture from seeping into the cold room and compromising the stored goods.

4. Vapor Barrier Films

Vapor barrier films are essential for cold room walls and ceilings to prevent the infiltration of moisture and condensation. These films act as a barrier, reducing the risk of mold growth and maintaining the integrity of the cold room's insulation. When combined with insulated panels, vapor barrier films enhance the cold room's thermal efficiency and overall performance.

5. Thermal Doors

Cold room doors play a crucial role in maintaining temperature integrity and preventing heat ingress. Opt for thermal doors with proper insulation to minimize temperature fluctuations and reduce energy losses. The doors should have a reliable sealing mechanism to ensure an airtight closure, keeping the cold air inside and preventing warm air from entering.

6. Antimicrobial Coatings

Applying antimicrobial coatings to the interior surfaces of the cold room can help prevent bacterial growth and maintain a hygienic environment. These coatings inhibit the growth of microorganisms, reducing the risk of contamination and ensuring the safety of stored goods.

7. LED Lighting

When it comes to lighting within the cold room, LED lights are the preferred choice. LED lights produce minimal heat and consume less energy, making them energy-efficient and less likely to impact the cold room's temperature. They also provide consistent and bright illumination, ensuring visibility and ease of operation within the cold storage facility.

Conclusion

Constructing a cold room with the right materials is crucial for maintaining the quality and safety of perishable goods. Insulated panels, stainless steel surfaces, HDPE, vapor barrier films, thermal doors, antimicrobial coatings, and LED lighting are among the best materials to consider when building a cold room. By selecting the appropriate materials, you can create an efficient, hygienic, and temperature-controlled environment that ensures the preservation and longevity of your stored goods.

FAQs

Q. Can I use regular doors for a cold room?

A: It is not recommended to use regular doors for a cold room. Regular doors lack proper insulation and sealing, which can lead to temperature fluctuations and increased energy consumption. Thermal doors designed for cold rooms provide the necessary insulation and sealing to maintain temperature integrity.

Q. Are there specific temperature requirements for cold rooms?

A: The temperature requirements for cold rooms depend on the type of goods being stored. Different perishable goods have specific temperature ranges for optimal preservation. For example, food items may require temperatures ranging from -18°C to 4°C, while pharmaceuticals may require temperatures as low as -70°C. It is essential to design the cold room to meet the specific temperature needs of the stored goods.

Q. Can I install shelving and racks in a cold room?

A: Yes, you can install shelving and racks in a cold room to maximize storage space and organize the stored goods. When selecting shelving and racks, choose materials that are compatible with the cold room environment, such as stainless steel or coated materials that resist corrosion and moisture. Additionally, ensure that the shelving and racks do not obstruct air circulation for efficient temperature distribution.

Why Choose KendallCool?

ISO 9001 Certified Manufacturing

Exported to 30+ Countries

Customized cold room solutions